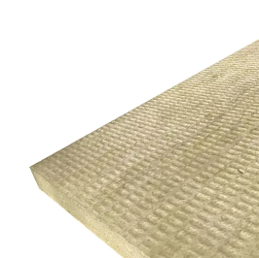

What are Basalt Fibers?

In brief, Basalt Fibers are produced from basalt rocks by melting them and converting the melt into strands of filaments, making up the fibers. The process is very similar to the one, making fibers from Glass. One large difference is, that in the glass fiber making many ingredients are blended together, in order to make up for the desired chemical composition. When melting Basalt, the mined igneous rocks (or lava rocks or magmatic rocks) are used from one or perhaps multiple mines in order to guarantee identical chemical consistency, over a long period of time.

How do Basalt Fibers compare with Glass Fibers?

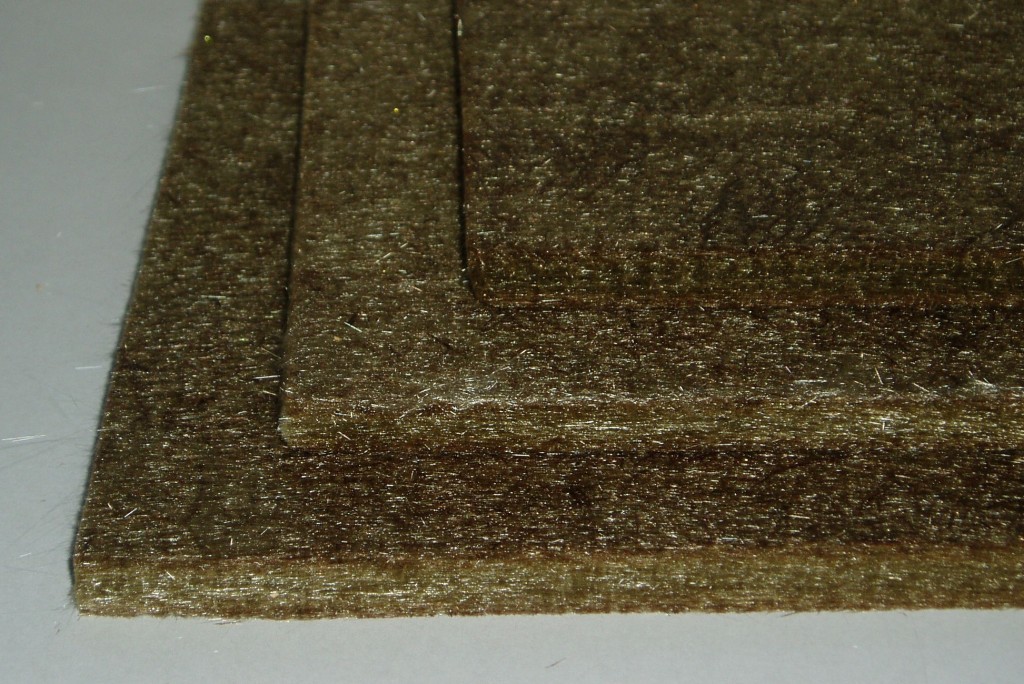

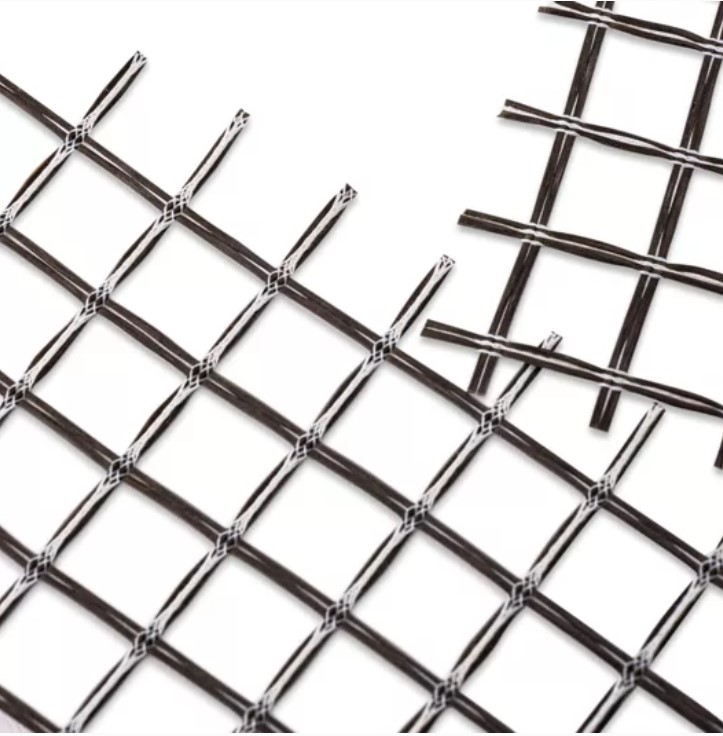

In general, almost any Glass Fiber product existent could be replicated with Basalt Fibers. This is due to the fact that Basalt Fibers are manufactured in almost identical variances of filament thicknesses (measured in microns) and densities (measured in the yield / lb or grams).

Furthermore, Glass Fibers and Basalt Fibers behave very similar during textile processes.

Last, but not least, the binder applied to the filaments, in order to keep them flexible and to prevent them from sticking together during the cooling process are designed for similar final applications.

Since the Basalt fibers are not made from a blended mix of components, thus the processes are simplified, it implies Basalt Fibers should be obtainable at a lower cost than Glass Fibers; but the fact is, Glass Fibers are made in much larger production runs, plus the melting temperatures for the most common Glass Fibers are lower than those for Basalt. This results in Basalt Fibers being a higher cost alternative to Glass Fibers. That said, there are distinct advantages of Basalt Fibers over Glass Fibers or other Technical Fibers.

When to use Basalt Fibers over Glass Fibers or even other Technical Fibers?

On other pages of this site, we will compare Basalt Fibers with various Glass Fibers, but also other Technical Fibers, such as Carbon, Kevlar, Nomex, etc, and it will illustrate the various advantages of those fibers.

In terms of Glass Fibers, It is worth mentioning that the chemical composition of Glass Fibers have been further developed to optimize its use in the desired final applications. E.g.

- E-Glass has been developed to improve on Electrical Resistance for better electrical insulation.

- S-Glass has been developed to be stronger in the linear direction, for ballistic applications.

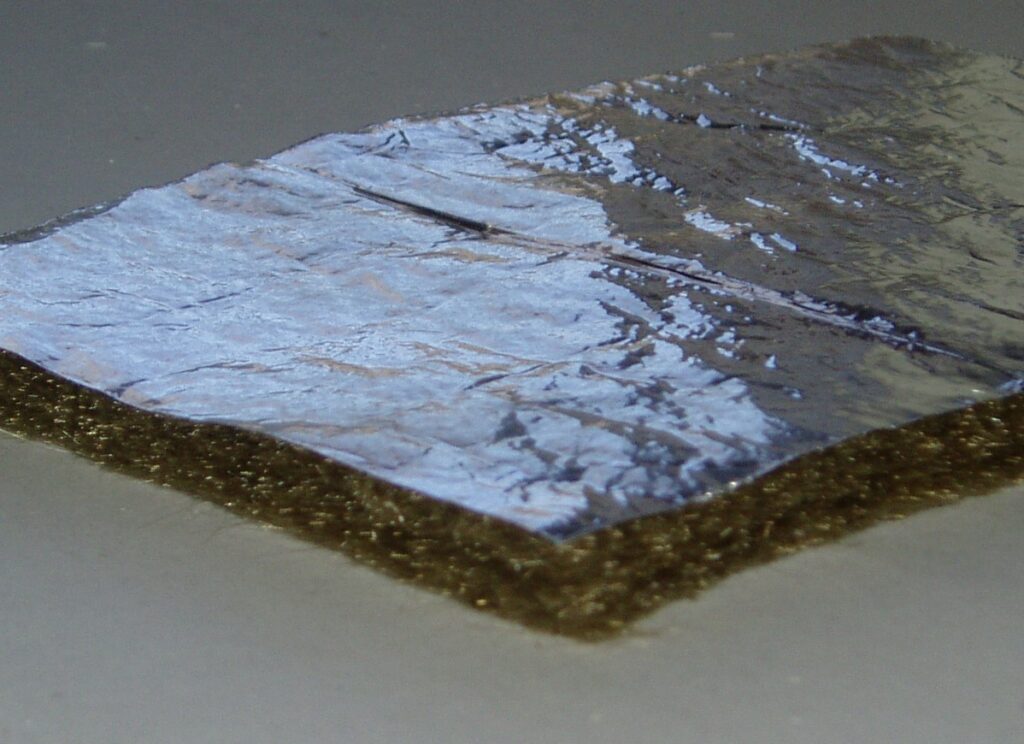

- Silica Glass has been developed for higher temperature resistances, for high temperature applications.

- there are a few more…

The Application Engineer will look at chemical compositions, binders, filament thicknesses, densities, properties under certain environmental conditions and determine the best fiber to choose from. This site will provide technical data to aid in this process.

Once the Application Engineer understands the differences, he/ she then can also compare the cost of individual fibers to determine if the use of an alternative may be advantageous. This is a difficult question to answer, as e.g.

- A basalt fiber is stronger than a standard Glass fiber in the linear direction. This implies, one can use less material to achieve the same desired physical properties. This in return would imply you can make a lower weight product. In the case of a flying object like a plane or a drone, this can make a big difference, as the payload can be higher or the reach can be further.

- A Basalt fiber has a higher alkaline resistance in comparison to a standard glass fiber. In concrete, Basalt would contribute to more longevity in the application.

- A Basalt Rebar does not expand and contract under temperature differences, as much as a Steel Rebar. When using Steel Rebars in construction and facing various temperature changes, it will expand more than Basalt Rebars do. This leads to unwanted cracks. This ultimately reduces the longevity of bridges, Buildings or roads which will need to be repaired constantly, due to that effect.